I. Introduction of Hybrid Waterproof roofing underlayment

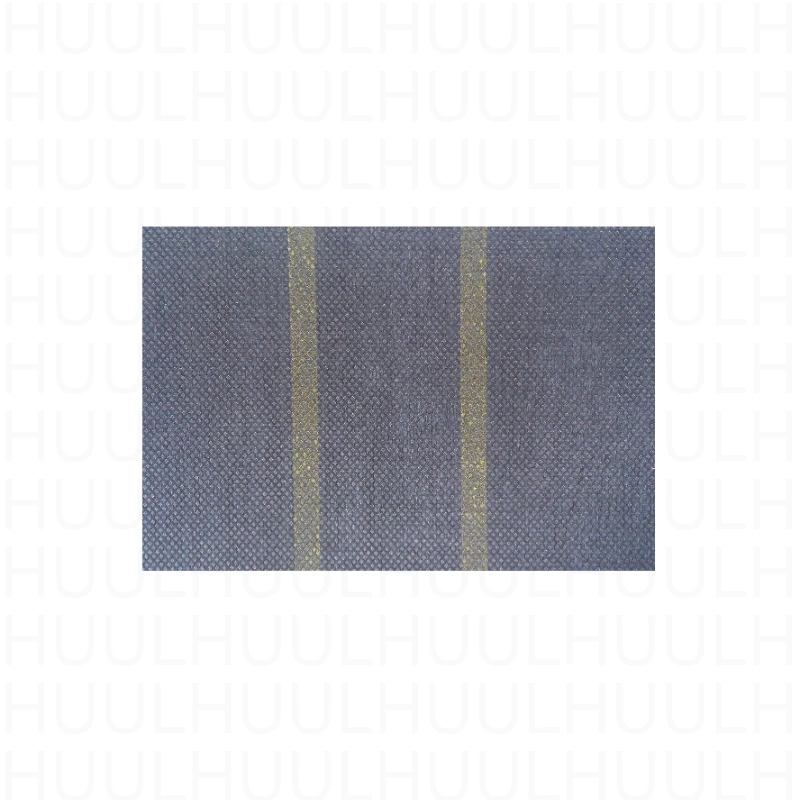

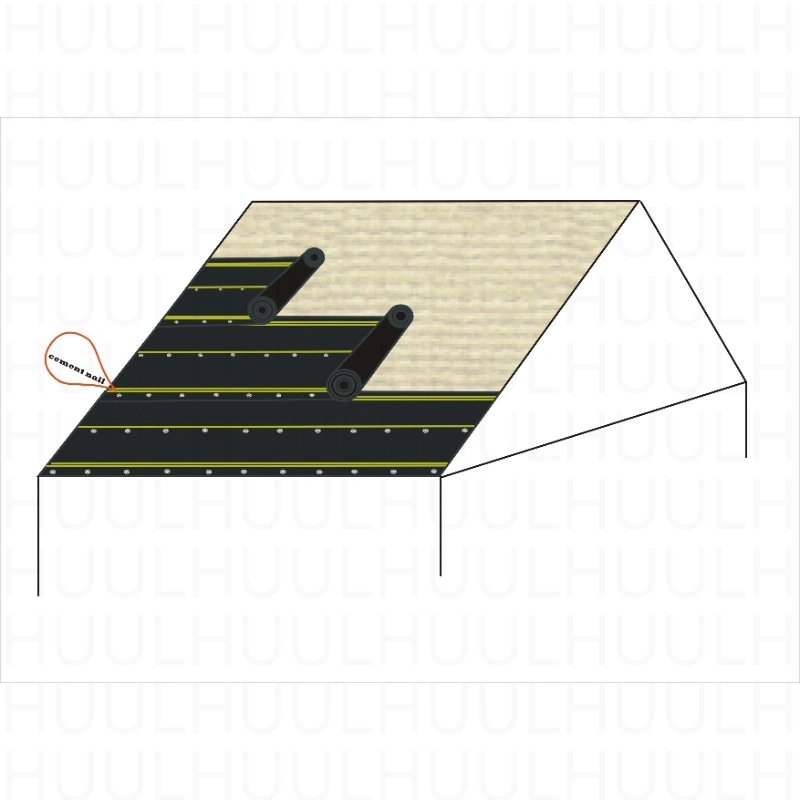

hybrid Waterproof roofing underlayment is an 8layer laminated roofing underlayment consists of multiple

layer of asphalt, synthetic fiber, non-woven, and HDPE, provides a vital second layer of protection of the

building for waterproofing, and to prevent roof damage from rain or snow. Its construction results in high

strength, low weight, unmatched tear resistance and long life tendency also almost half the cost of other

synthetic underlayments.

2.Types of Hybrid Waterproof roofing underlayment

3.Specification of Hybrid Waterproof roofing underlayment

1)Anti-leaking and tearing: passed 110 mph wind test and 4-hour water spray test with cap and roofing nails.

2)Excellent tensile: CD≧300, MD≧300

3)Wrinkle free: lay flat,stay flat, but flexible

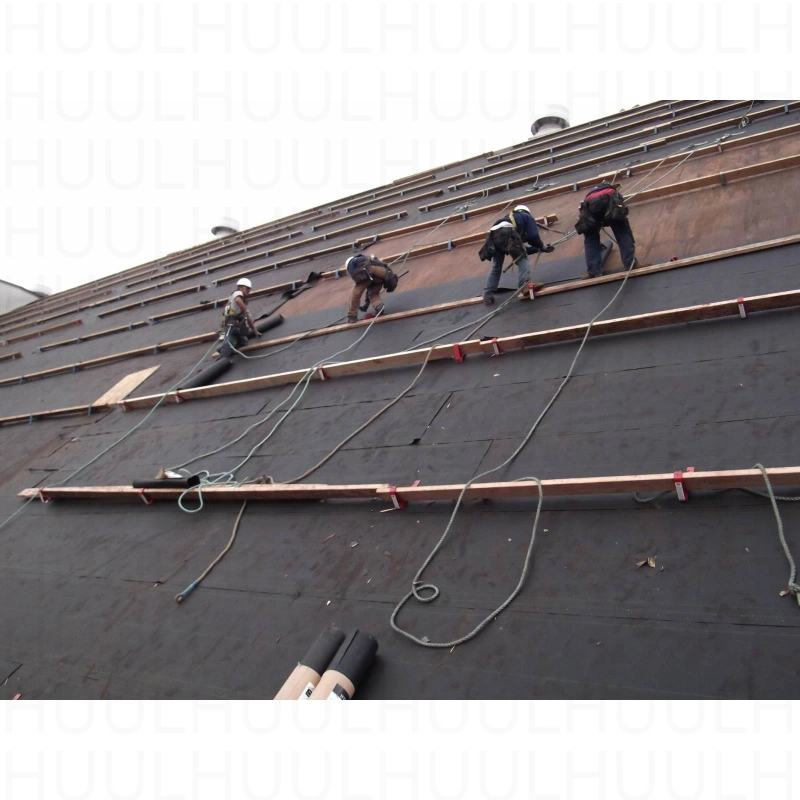

4)Anti-skidding: textured surface provide good walking surface during installation

5)Excellent stability: strong fiber reinforcement, give the excellent elongation and life tendency

6)8-layer construction hybrid technology combines asphalt, synthetic fabric, HDPE

7)Lightweight: faster and quicker, over 450sq.ft coverage per roll, easy to carry and easy

installation

8)High temperature resistance: up to 260℉

9)ASTM standard: meets ASTM D 1970 for nail sealing ability of roofing underlayments

10)UV endurance: up to 90 days exposure for roof finishing

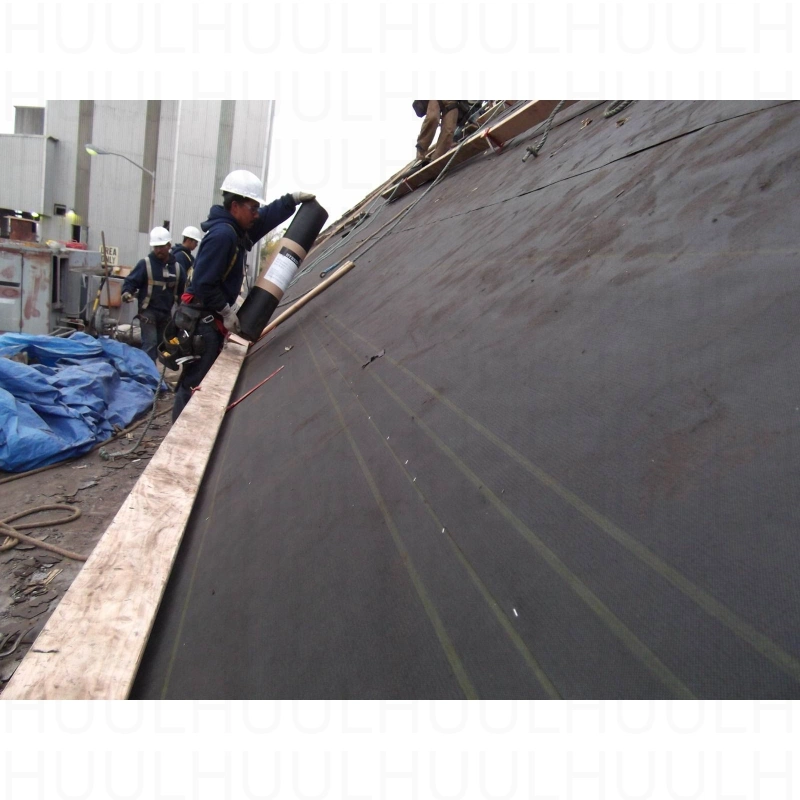

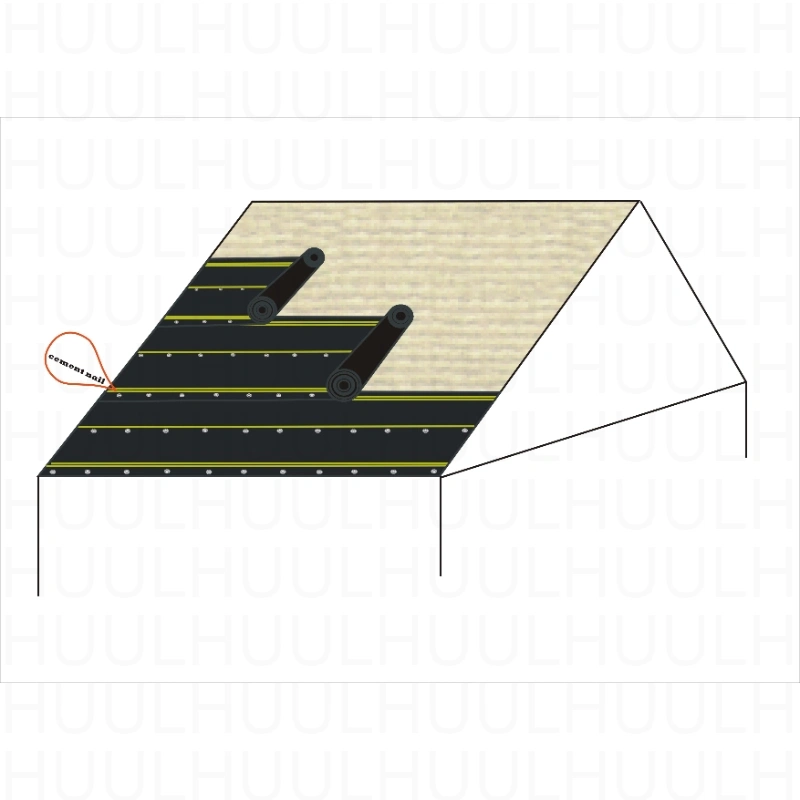

4. Applications of Hybrid Waterproof roofing underlayment

1)To serve as an essential part of the roofing system

2)To serve as a temporary roofing cover during construction

3)To serve as a safety net

5.Advise for shipping the waterproof underlayment

By 20ft container

Unit weight = 460gams/㎡

Roll weight = 20kgs

Roll width=95cm

Roll length=44.2m

Roll diameter = 18.5-19.5cm

rolls into one iron pallet, 20 pallets into 20ft container, total 500rolls (gross weight around

11tons, total around 21000 ㎡